[one_full last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][fusion_text]MatSol’s Principal Scientist & Director, Dr Paul Hugget has a wealth of experience in the mining game. When asked about Material certificates for raw materials his response probably wasn’t what you’d expect.

“Just because a supplier provides a material certificate for a batch of raw materials, doesn’t necessarily mean the products are always correct for the application. Steel suppliers will often provide a mill certificate which will show a chemical analysis, mechanical properties (such as tensile strength), and sometimes hardness, etc. However whilst these values will normally be within the required specification, there can be other problems with the material, such as general defects (inclusions, porosity), microstructural issues (such as “banding”, micro-porosity, carbides, coarse grain size, etc) that will effect the performance of the material in service.

When the properties of the material are critical for a specific purpose, such as a structural requirement, it is essential that samples from the supply be properly analysed by a third party to ensure the materials conform to the design and specification requirements. Care should also be taken when procuring raw materials to ensure the right questions and requirements are requested from the suppliers.”

[/fusion_text][/one_full][fusion_text]

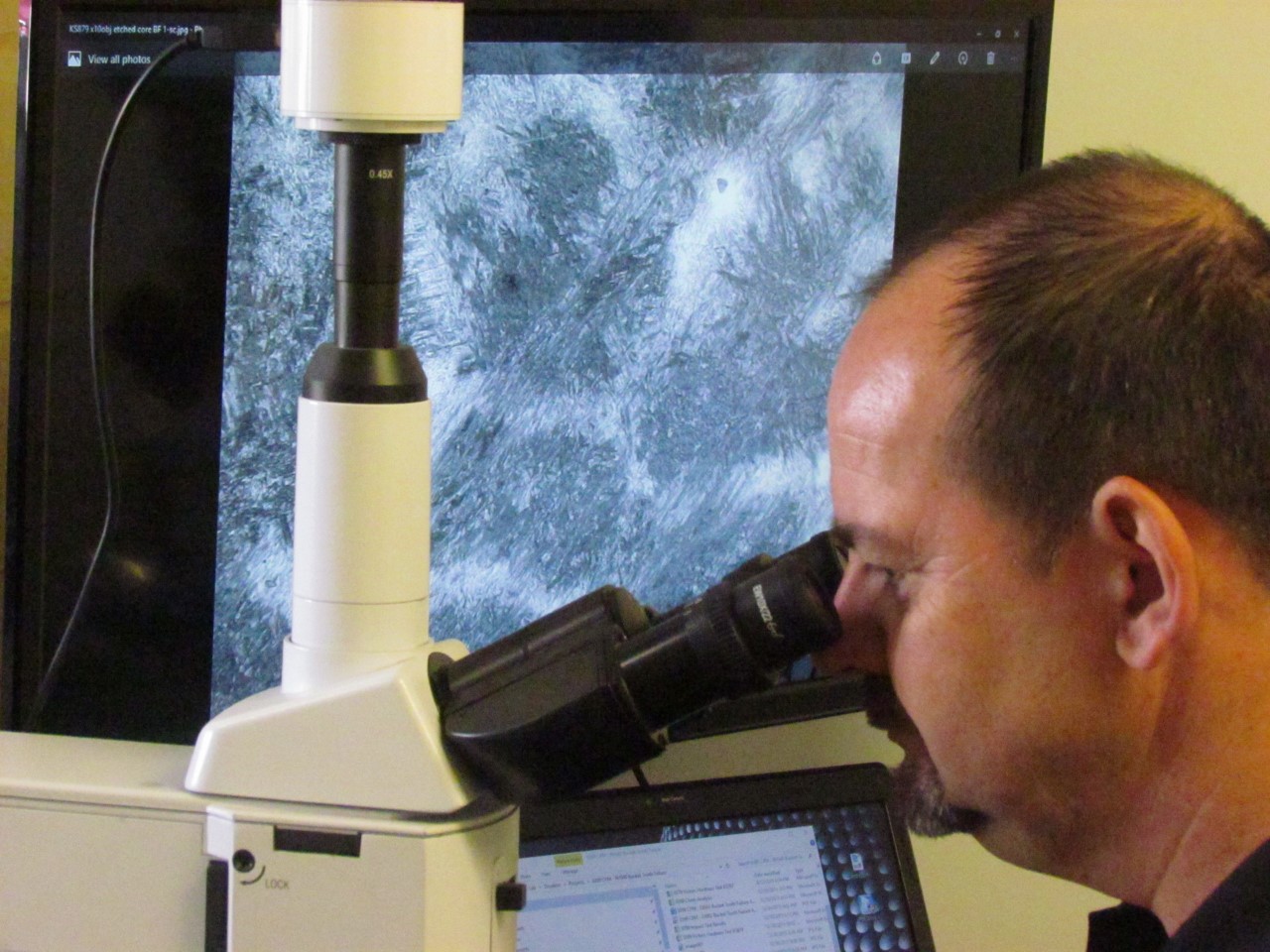

Microstructure of quench and tempered steel showing the presence of allotriomorphic ferrite, which reduces the mechanical properties and hardness of the material.

Using an optical microscope to view the microstructure of quench and tempered steel showing, the presence of allotriomorphic ferrite, which reduces the mechanical properties and hardness of the material.

[/fusion_text][one_full last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=””][fusion_text]MatSol have worked closely with IMEC on a number of projects from failure analysis to paste rheology testing and pipeline friction loss reports. Check out their website for more info – MatSol or call on (+61 +8) 6468 4118[/fusion_text][/one_full]